The incorporation of milling by-products, in particular bran, into starch-based extruded snacks allows manufacturers to address two consumer demands at once, i.e., those for goods that are more sustainably produced and of higher nutritional value. However, the higher fiber content in bran than in refined cereal flours poses a limit to the amount that can be included without compromising the quality of extruded snacks, which crucially depends on expansion. Thus, several studies have focused on the effect of bran on the physicochemical characteristics of extruded snacks, leading to the need to review the recent findings in this area. Opportunities and potential solutions of bran-enriched snacks are addressed, and several current knowledge gaps are highlighted.

1. Introduction

The global extruded snacks market was valued at USD 51.59 billion in 2019 and is expected to grow by more than 4% until 2026 as a result of changes in the eating habits of consumers and the growing demand for ready-to-eat foods [1]. Extruded snacks are convenience products and their low moisture content (around 4–6%) makes them shelf-stable. The versatility of their manufacturing process facilitates innovation in this product category, allowing the use of various ingredients and/or nutrient-rich constituents to make attractive products.

Cereal-based snack foods cover a wide range of ready-to-eat products, such as popcorn, pretzels, breakfast cereals, and expanded products. The structure and texture of such snack foods are the results of their respective manufacturing processes, which can involve operations like baking, deep-frying, or the topic of this review, extrusion cooking. This technology can be tailored to yield various products: direct-expanded (or second-generation) snacks, semi-finished product pellets (or third-generation snacks), or co-extruded products [2].

As these products are specifically formulated to allow for maximum expansion and thus starch gelatinization, extruded snacks have often been criticized for their poor nutritional profile (i.e., high starch content and glycemic index [3,4]). At the same time, extruded snack products are usually low in protein, vitamins, minerals, and dietary fiber [4]. Recently, efforts to produce extruded snacks to address these nutritional shortcomings have increased, and breakfast cereals and snacks are anticipated to be among the fastest-growing segments in the global dietary fiber market [5]. An increase in the dietary fiber content can be achieved via using: (1) Wholemeal instead of refined flours; (2) Feed mixes containing flours with high dietary fiber contents such as barley, oat, pseudocereals or pulses; (3) Bran as an ingredient; or (4) Commercial sources of purified dietary fiber preparations, typically soluble fibers such as inulin, pectin, or psyllium. The latter approach makes it possible to achieve label claims of the product being a “source of fiber” or “high in fiber” (3 versus 6 g of dietary fiber per 100 g of serving) [6] with minimal changes in formulation and product quality. The use of whole grains and/or their milling fractions (especially bran) has a positive effect on the nutrient composition by increasing the contents of protein as well as fiber and other bioactives [7]. In a recent survey of breakfast cereals available in Italy, bran-containing products were significantly higher in protein but lower in energy content than all other categories [8]. In addition, formulating foods to contain by-products addresses the crucial need for a more sustainable food production. In this context, several recent articles have highlighted compositional and functional aspects of extruded snacks formulated with by-products [9,10,11], or summarized the effects of cereal fiber on microstructural, technological, and sensory attributes of products either extruded at low (pasta) or high (snacks) temperature [12]. If a manufacturer was aiming to develop a novel bran-enriched extruded product with the help of a multidisciplinary team, a debate between nutritionists and food technologists might emerge on how much bran should be included. On the one hand, more added bran maximizes the nutritional benefits, but on the other hand, the negative impact of fiber on physicochemical features of snacks and consumer acceptability is usually evident even at low percentages. Almost a decade ago, Robin et al. [13] pointed out the challenges of using fiber in extrusion and discussed some approaches for suitably processing the fibers to facilitate their inclusion. Since then, several studies have explored the opportunity to include fibers either as isolated compounds or in the form of bran in extruded snacks. Researchers have expanded the range of used raw materials, such as through the inclusion of legume bran (i.e., the hulls) as well as bran pre-treatments.

The focus of this review revolves around the challenges of producing bran-enriched snacks and potential solutions to assure product quality (Figure 1). This work aims to provide an overview of recent approaches for improving the features of bran-enriched snacks involving bran pre-treatment or processing optimization. It will conclude with a discussion on crucial research needs to better understand the relationship between structural attributes of the raw materials, processing conditions and product quality, so that results from different studies are easier to compare.

Figure 1. Motivations for enriching extruded snacks with bran, as well as potential issues and strategies to address them.

2. Strategies to Enhance the Quality of Bran-Enriched Snacks

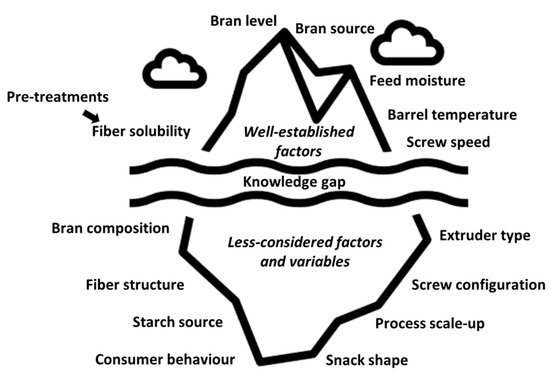

Bran enrichment can increase the content of protein, fiber and other bioactive compounds in snacks whose main component is starch. However, the enhanced nutritional properties come at the expense of inferior physical features of the final product (Figure 1). A balance between nutritional and technological quality might be achieved by adopting two approaches. On the one hand, several treatments can be used to modify the dietary fibers—mainly the insoluble fraction—prior to using the bran in food. These treatments involve mechanical, chemical and biotechnological processes. On the other hand, when a new ingredient is included in a recipe, both enrichment level and processing conditions can be optimized. While there is broad consensus among studies about the improvement of certain factors, there is also a knowledge gap (Figure 2).

Figure 2. Factors and process variables most frequently investigated versus those that are rarely addressed in studies on bran-enriched extruded products. There is broad consensus among studies about the importance of factors positioned above the knowledge gap (the iceberg representing our understanding of how to manipulate the factors to counteract quality loss upon bran addition). The relationship between product quality and terms positioned below the knowledge gap remains to be elucidated by future studies.

2.1. Bran Pre-Treatments

Pre-treatments that convert a portion of the insoluble fiber into soluble fiber may be effective in preventing the loss in product quality observed upon bran addition, as it increases physicochemical compatibility with the starch

[1]. Dietary fiber can be depolymerized by the use of enzyme preparations, microbial fermentation, or addition of acids or bases.

2.1.1. Particle Size Reduction

Particle size reduction is an effective way to increase expansion and consequently decrease density. For instance, the porosity of rye extrudates was significantly higher when material of 28 µm particle size (as opposed to 143 or 440 µm) was used

[2]. Finely milled rye bran especially benefited from pre-hydration, and extrudates, where this pre-hydrated bran was combined with refined rye flour/waxy corn starch (70/30) blends, were of lower density and more expanded than extrudates where water was fed to the dry mix in the barrel

[3]. Pre-hydration also affected water absorption indices. However, air cell diameter and porosity were not affected, and crispiness was only improved by lower particle sizes, but not by pre-hydration. It was proposed that pre-hydration may only lead to beneficial effects on microstructure if bran is incorporated below a certain ‘critical’ percentage into the dry feed.

2.1.2. Chemical Approaches

Cleavage of ester links between ferulic acid and bran polysaccharides (arabinoxylans) occurs under alkaline conditions. A combination of corn flour and corn bran that had undergone alkaline treatment gave an extruded product with significantly higher expansion than the product made from corn flour and untreated bran

[4]. Combining corn flour with only the bran portion that was solubilized by the alkaline treatment increased expansion even more. A treatment like this would also disrupt cell wall architecture, which may have led to these differences, aside from the higher solubility. In addition, the use of such bran (fractions) may also lead to lower apparent viscosity during the extrusion run, allowing more bubbles to form and grow

[4].

The hydrolysis of glycosidic bonds during extrusion can be promoted if acids are added to the feed mix. This has recently been shown for wheat bran extruded in the presence of 2 or 5% citric acid, where the content of water-extractable arabinoxylans increased in a dose-dependent manner (2.4 and 3.1%, respectively, versus 0.6 in the extruded bran and 1.8 in bran extruded without acid at the same moisture content)

[5]. The acid-extruded samples had higher ratios of xylose to arabinose, indicating a lower degree of branching. In addition, there was a slight increase in free arabinose and a considerable increase in free ferulic acid. While the viscosity of aqueous extracts was relatively low in absolute terms, the values of acid-extruded bran were higher than for the control. Extrusion with acid led to the degradation of compounds other than arabinoxylans as well. In some instances, this led to a desirable change in terms of nutritional aspects (e.g., a decrease in phytate), while degradation of other compounds would not be beneficial (e.g., when the feed mix contained 5% citric acid, most of the fructans were hydrolyzed to monomers). Extrusion in the same conditions without acid did not lead to fructan degradation. The authors hypothesized that in comparison to regular extrusion cooking, cells would be ruptured and more disintegrated after inclusion of acid, which light microscopy images confirmed.

A different approach to acidifying a bran sample is to incubate it with a lactic acid solution to mimic the exposure which occurs during fermentation with lactic acid bacteria

[6]. This incubation procedure resulted in lower melt viscosity, product density and hardness, as well as significantly more expansion. Lower viscosity values across the whole temperature range in pasting profiles indicated starch depolymerization.

2.1.3. Bio-Technological Approaches

Treatment of wheat bran with xylanase increased crispness in extrudates prepared from an 80:20 mix of refined rye flour and wheat bran

[7]. Washing rice bran with water removed the majority of soluble fiber but resulted in a concentration of insoluble and total dietary fiber by removing a large portion of starch and lipids

[8]. As an added benefit, phytate contents were also decreased by water washing. The washed bran was then subjected to different xylanase treatments, which resulted in the highest contents of soluble material when bran was first extruded, dried, and milled, then incubated with xylanase. However, this type of bran was not used to produce snacks.

Several studies have investigated pre-fermentation of rye bran with microorganisms that produce exopolysaccharides. Similar to added hydrocolloids like guar gum

[9], these carbohydrates can improve textural properties of the so-fermented bran-containing extrudates. Additional inclusion of commercial α-amylase and xylanase further increased expansion and lowered the density, and up to 40% of refined rye flour could be substituted with bran without significantly changing these parameters compared to the control (i.e., extrudate produced exclusively from refined rye flour)

[10]. The addition of these enzymes resulted in slight decreases in total dietary fiber content, which the authors attributed to hydrolysis of β-glucans and fructans, i.e., generation of low molecular weight soluble fiber that may not precipitate in 78% ethanol and thus not be determined via enzymatic-gravimetric dietary fiber measurements as in official method 991.43

[11]. In earlier work, the authors had determined side activities of the enzymes

[12]. The treatments also increased cell size of extrudates.

3. Knowledge Gaps and Future Perspectives

With shifting consumer demands over the past decades, food reformulation with the purpose of enhancing products’ nutritional value has been investigated by numerous studies. In this context, bran represents a relatively widely available and economic vehicle of fiber, protein and phenolic compounds to enrich extruded snacks which are otherwise mostly comprised of starch. Although bran enrichment generally causes a decrease in expansion rate and an increase in both density and hardness, some studies showed no such effect or even the opposite trend

[13][14][15]. Using different sources and percentages of bran, different grains as the main ingredient, different types of extruder and processing conditions might account for such contrasting results. Such diverse outcomes make it hard to pinpoint what results can be expected from a certain set-up, but at the same time highlight the current knowledge gaps and drivers for further research. The relationship between bran composition and product functionality should be better addressed and, furthermore, should be addressed in a more systematic way. The milling conditions as well as the source of bran affect its fiber, protein, starch and lipid contents, which in turn affect product features. For instance, bran from white, red or purple wheat—which are characterized by different chemical compositions—affected snack quality to different extents

[13]. Taking into consideration that decorticated pulses are becoming more common in cereal-based products

[16][17], the potential use of pulse bran in snack production should be further investigated.

The role that structure and functionality of bran components might play deserves to be elucidated. Information about which starch source is most suitable for bran-enriched formulations is scarce. Despite recent reports that illustrate the impact of starch characteristics, including amylose to amylopectin ratio, on the physicochemical properties of extruded snacks

[18][19][20], there is a notable lack of information about why studies combined a certain bran type with a certain starch source. In other words, it is unclear if rice, corn or wheat behave in a similar way or if one of them may better counteract the negative impact of bran addition (and as to whether certain starch characteristics would influence that). Such information could take out some of the “guesswork” when using novel raw materials in future studies. However, extrusion will likely retain a certain empirical aspect in the foreseeable future.

Bran enrichment also requires a “food design” approach, which includes the assessment of those variables that mostly affect product quality and thus their optimization. In this regard, the roles of feed moisture, barrel temperature, and screw speed on snack features have been widely addressed, whereas fewer authors have pointed out the importance of screw configuration on bran functional properties

[21], leaving room for further investigation on snack quality. Moreover, since most of the studies were carried out on a pilot scale, the scale-up of the process needs to be considered for large scale production of bran-enriched extruded snacks. It was recently shown that higher SME, and thus greater structural disintegration of wheat bran, can be achieved via use of an industrial scale extruder compared to pilot-scale extrusion

[21].

Among extruded snacks, direct expanded snacks make up the majority of the products on the market, and, thus, numerous research articles have focused on this snack type. On the other hand, few studies have been published on the most recent extrusion-cooked snack category, i.e., co-extruded snacks. For such products, there are additional quality requirements, i.e., a compact outer shell and an evenly shaped hole to contain a savory or sweet filling. Regardless of the type of snack, expansion rate, bulk density and hardness are the main indices considered for quality assessment. However, other attributes that contribute to the overall quality of extruded snacks, including porosity and cell size distribution, have been poorly considered so far. Moreover, considering that textural attributes might depend on product shape

[22], it should be considered if, for instance, cylindrical snacks might counteract bran enrichment better than ring-shaped snacks. Additionally, among the relatively neglected aspects of bran inclusion into extrudates are effects on flavor, which can be affected as bran (and whole grains in general) is characterized by higher bitterness

[23]. Electronic noses and tongues have been proposed to successfully evaluate the contribution of different chemical species in determining aroma and tastes in wholegrain pasta and may be useful tools for extrudates as well

[24]. Bran pre-treatments that use acids, enzymes or fermentation to lower the pH also affect sensory properties. Finally, in addition to evaluating the impact of bran addition on the sensory quality of snacks, studies on consumer behavior are worthy of interest. For example, the effect of fiber information on consumer’s acceptability and expectation has not been investigated for this kind of product. Establishing the right balance between the expected health benefit of eating fiber and perceived product liking might be useful to food developers to increase fiber content in snack formulations without worsening sensory attributes and pleasure

[25]. In addition, food neophobia should be further investigated to define whether this behavioral attitude could impact hedonic perception. Finally, as pointed out for snacks enriched in other industry by-products

[26], information on consumer behavior needs to be completed with studies focused on consumers’ willingness to pay for bran-enriched snacks. Several studies have achieved quality improvements via pre-treatments; however, these need to be balanced with their costs.