Lingonberry (Vaccinium vitis-idaea L.) is a health-promoting small fruit crop rich in antioxidant metabolites that helps to reduce the incidence of degenerative diseases. Being heterozygous, lingonberries cannot preserve genetic characteristics through seed propagation. Conventional vegetative propagation, although it produces true-to-type plants, is not economically viable. In vitro propagation can multiply plants much faster than conventional methods. A liquid cultures system under a bioreactor micropropagation system is of significant importance to increase the multiplication rates of in vitro-produced shoots. Enhanced vegetative growth and variation in biochemical constituents are observed in micropropagated plants. Clonal fidelity, although it may be a serious problem for commercial micropropagation, can be verified efficiently by molecular markers.

1. Introduction

Lingonberries (

Vaccinium vitis-idaea L.; family Ericaceae) are evergreen dwarf, rhizomatous, circumboreal woody shrubs

[1]. They grow on heath areas on rocky places and dry peat soils and are economically important berry species to northern regions of the world

[2]. There are many common names of lingonberries depending on regional nomenclature, such as partridgeberry or redberry in Newfoundland and Labrador; foxberry in Nova Scotia of Canada; airelle rouge in France, tytlebaer in Germany; puolukka in Finland; cowberry in Britain; kokemomo in Japan; and rock, mountain, dry ground or low bush cranberries and linberry in other parts of Canada and Alaska

[3][4][5]. Throughout history, it has been grown as a fruit crop, a medicinal plant and a landscape ornamental ground cover

[6]. The fruits can be consumed raw or used in juices, wines, pastries, jams, jellies, ice creams, cocktails and desserts

[7][8].

Lingonberries gain significant importance in human diet for their rich source of vitamin C, omega-3 fatty acids, polyphenols and high antioxidant contents conferring health benefits. In lingonberries, 63–71% of the total phenolic contents are proanthocyanidins

[9], which can defend against plant pathogens

[10]. Flavonoids, phenolic acids, lignans and complex phenolic polymers (polymeric tannins) are the chemical substituents present in lingonberries and are richer sources of flavanols than many vegetables and fruits that are commonly used

[11]. Lingonberry flavanols show antioxidative, anti- inflammatory, antibacterial, antiviral, antitumor, antifungal and vasoprotective activities

[12][13]. Anthocyanins, which contribute to the red color of lingonberries, are one of the valuable phytochemicals showing protective effects against damage caused by radiation

[14]. More than 116 anthocyanin and flavonoid compounds were isolated and identified primarily from lingonberry fruits or leaves

[13][15]. Cyanidin-3-galactoside, cyanidin-3-arabinoside and cyanidin-3-glucoside are the three main anthocyanins in lingonberry

[16][17][18]. Jin et al.

[8] obtained 4.12 ± 0.18 mg g

−1 of anthocyanins in lingonberry pomace, with 3.36 ± 0.14 mg g

−1 of cyanidin-3-galactoside, 0.15 ± 0.01 mg g

−1 of cyanidin-3-glucoside and 0.61 ± 0.03 mg g

−1 of cyanidin-3-arabinoside. Lingonberry leaves and fruits are used to reduce cholesterol levels and treat kidney and bladder infections, stomach disorders and rheumatic diseases

[3][19]. Lingonberry has highest content of resveratrol which are strong antioxidants with cancer chemopreventive activities

[20], and they even help to reduce the threat of heart disease

[21][22]. Lingonberry juice is helpful in protecting against urinary tract infection

[23], and it possesses anti-inflammatory effects that protect the kidneys from ischemic-reperfusion injury

[24]. Dietary supplementation with lingonberry reduces high-fat diet-induced inflammatory response and prevents kidney injury

[24][25]. Lingonberry products, together with cranberry products, are well known as natural remedies for the treatment of urinary tract infections

[26]. While the leaves of lingonberry have diuretic and urinary anti-septic properties, mainly related to their high content of tannins, arbutin (hydroquinone-ß-D-glucopyranoside) and arbutin derivatives

[23].

Though the promising health benefits of lingonberries have inspired efforts to develop and magnify their commercial production

[27][28], increasing their production throughout North America remains a challenge. Lingonberries are categorized under minor berries like black (

Ribes nigrum L.) and red currants (

R. rubrum L.), chokeberries (

Prunus virginiana L.), cloudberries (

Rubus chamaemorus L.), elderberries (

Sambucus nigra L.) and gooseberries (

R. uva-crispa L.)

[29], and are not immediately available in the marketplace as blueberries (

V. corymbosum L.,

V. angustifolium L., etc.) or cranberries (

V. macrocarpon L.) are. Although lingonberries are native to the Canadian Pacific Northwest and northeastern Canada, they are not cultivated far and wide. Lingonberry is harvested mainly from native stands, but its high demands for industrial processing have led to the development of cultivars for commercial production. Currently, researchers at St. John’s Research and Development Centre of Agriculture and Agri-Food Canada in St. John’s, Newfoundland and Labrador, Canada, are developing high quality hybrids between European and Canadian lingonberries

[3]. At present, commercial cultivation with European cultivars is available in small scale in Europe and North America, and most of the annual lingonberry harvest is from native stands

[5]. In Newfoundland of Newfoundland and Labrador province Canada, lingonberries are grown in the wild, where 96,501 kg per year are commercially harvested

[30]. The average yield of wild lingonberry was from 1900 to 3100 kg ha

−1 over two growing seasons, 2011 and 2012, in Southern Labrador, Canada

[31], and this is a relatively new endeavor in North America.

Being genetically heterozygous, it is not desirable to reproduce lingonberries from seeds because of the loss of their original form. Though propagation by vegetative means can conserve genetic integrity in lingonberries, conventional vegetative propagation is not economically feasible due to slow rhizome development and the fact that plants propagated by stem cuttings have brief life spans

[32]. Micropropagated plants can proliferate more rapidly than conventional methods. Micropropagation is used for the speedy establishment of plants and for early fruit production

[33][34][35]. Lingonberry plants raised through micropropagation were superior to those obtained by stem cuttings for fruit yield, rhizome production and vigor

[36][37].

2. Taxonomy and Distribution

Lingonberries belong to the genus

Vaccinium L. of subfamily Vaccinioideae in family Ericaceae, which contains about 4250 species in 124 genera

[38]. The plants are dwarf and consist of a tap root system with rootlets. Adventitious roots are grown along the nodes of the stems and rhizomes. The flowers are small and light pink, with the inferior ovary producing dark red globose berries. Flowering occurs at the beginning of June and fruit matures at the end of August or the beginning of September. The fruits have an acidic taste (pH of 2.5) and contain tanins (7–21 mg g

−1 fresh weight), anthocyanins (1–27 mg g

−1 fresh weight) and total sugars (around 6%)

[39]. The total rhizomes account for 80% of the total plant biomass

[40]. Lingonberry plants are perennial eudicots, an evergreen shrub that extends from artic to north temperate regions in Eurasia and North America. They are categorized into two subspecies: ssp.

vitis-idaea L. and ssp.

minus (Lodd)

[41]. Plant size is the main difference between the two subspecies, with ssp.

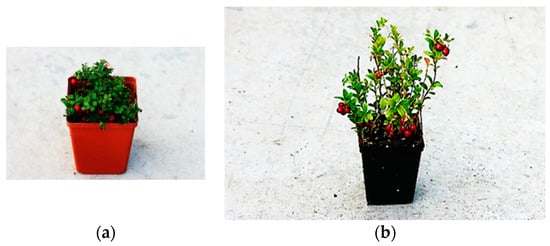

minus being considerably smaller in height and leaf size (, ).

Figure 1. Greenhouse grown lingonberry plants. (a) Vaccinium vitis-idaea ssp. minus; (b) V. vitis-idaea ssp. vitis-idaea.

Table 1. Differences between the two subspecies of Vaccinium vitis-idaea.

| Character |

V. vitis-idaea Ssp. Minus |

V. vitis-idaea Ssp. vitis-idaea |

| Variety [42] |

North American |

European |

| Race [43] |

Small arctic |

Large low land |

| Distribution [44] |

Iceland, Greenland, North America, northern Asia, Scandinavia |

Europe, Asia |

| Plant height |

Generally up to 20 cm |

Exceeds 30 cm |

| Leaf size [45] (Welsh 1974) |

Length: 1.0 cm; width: 0.5 cm |

Length: 2.5 cm; width: 1.0 cm |

| Crop per year [3] |

One crop |

Two crops |

3. Liquid Culture for Bioreactor Micropropagation

Although conventionally micropropagation is carried out on a semi-solid medium, the use of liquid medium is more efficient for large-scale micropropagation

[46]. Liquid media are more advantageous than semi-solid in many plant species as they can enhance in vitro shoot proliferation, regeneration, somatic embryogenesis, rooting, culture growth, developmental process and micro-tuberization

[47][48][49]. In liquid culture systems, the tissue is always in contact with the medium, stimulating the uptake of nutrients and phytohormones, which in turn leads to the uniform culturing of shoots and provides more rapid growth, yielding larger flesh and dry weight

[50]. In the beginning, liquid culture medium was used to produce somatic embryos, microtubers and organ cultures in vitro both in agitated and non-agitated vessels and in bioreactors

[51][52][53]. The continuous shaking of the liquid medium is known to provide aeration to the cultures, and this promote a larger growth and multiplication rate of the shoots

[50]. The amount of sugars, inorganic ions and phytohormones present in the liquid medium shows a greater direct impact on in vitro shoot growth than on those grown on agar

[50]. Agar medium contains inorganic impurities and limits diffusion rates

[54]. In liquid media, explants can be cultured in partial immersion (temporary immersion), where gaseous exchange is not hindered and explants can use nutrients efficiently

[46]. However, vitrification can be observed in in vitro-raised shoots as they are generally very sensitive to liquid media. This leads to the poor survival of tissue culture plants when they are transferred to ex vitro conditions. In vitro-derived plants are susceptible to environmental stress when grown ex vitro

[55][56]. This is because of the absence of agar concentration in the culture medium causing vitrification in the tissues

[57][58][59][60]. Hyper-hydricity has been proposed to define hyper-hydric malformations affecting in vitro-derived shoots in culture

[61]. The phenomenon was previously known and described under the term vitrification

[62]. Translucency, glassiness, vitrescence and glauciness are other less-used terms for this physiological disorder

[63]. Vitreous, vitrified or hyper-hydric shoots look turgid with a watery surface and are hypo-lignified. The problems of hyper-hydricity can be avoided by exposing the explant alternately to liquid and air in the vessel. Further, liquid culture systems offer the renewal of media without changing containers, as the ease of container cleaning may alter the culture period. Moreover, conventional micropropagation techniques are limited due to high cost of production at the industrial level. Liquid culture systems are helpful in overcoming this limitation due to cost reduction, as they can be less labor intensive and require less time for sub-culturing. Other advantages of liquid media include the easy replenishment of culture media, escaping or minimizing the numbers of subcultures and reducing the unit cost, as gelling agent is not needed as an addition in the media

[64][65].

3.1. Bioreactors

Bioreactors for in vitro culture range from 0.5–500 L in size and can be a jelly jar or a reformed microbial fermenter. Bioreactors are vessels widely used for the culture of organisms, including plants, cells and microbes to produce cells or metabolites

[66][67]. Bioreactor technology is also applicable to plant propagation. The application for plant propagation using the shake culture technique was initially reported in Begonia by Takayama and Misawa

[68]. Thereafter, the technique has been used in many plant species

[69][70][71]. Bioreactor micropropagation consists of culturing explants in liquid media with forced aeration, leading to the formation and multiplication of propagules including plantlets, microtubers, microcorms or bulblets. The major advantages of bioreactor micropropagation include

[72]:

-

The easy production and scale-up of a large number of plantlets in the minimum time.

-

Easy culture handling (inoculation and harvesting) with a reduced labor cost.

-

The close contact of explants in liquid cultures, allowing the quick uptake of nutrients for rapid growth.

-

Sufficient oxygen supply due to forced aeration for improved growth rate and multiplication.

-

The movement of cultures in bioreactors, resulting in the removal of apical dominance and rapid shoot proliferation and plantlet formation.

Bioreactors used for micropropagation can culture explants in continuously submerged conditions or can be immersed partially or temporarily in the medium. There are many types of bioreactors used in plant biotechnology; few have been provided with light conditions for culturing explants

[73]. Some other bioreactors have been fitted with pipes through which light was emitted

[74]. Bioreactors used for in vitro propagation can be mechanically or pneumatically agitated, non-agitated or temporary immersion types

[71]. The utility of a bioreactor depends on its cost-effectiveness and convenience of operation along with maintaining the culture quality. Temporary immersion (TIB) and stationary bioreactors (SB) have been used for the in vitro culture of lingonberries

[75].

3.1.1. Temporary Immersion Bioreactor (TIB)

Various TIB types are available, where the design is chosen based on the requirement of the specific plant culture sensitivity to hyperhydricity and culture costs

[69][76]. The TIB system is very useful for semi-automated in vitro propagation. It helps in controlling contamination, adequately supplying oxygen and nutrients and mixing. It requires less frequent sub-culturing, and it has the benefits of ease of medium changes and limited damage due to shearing. The RITA

® (recipient for automated temporary immersion)

[77] is a kind of TIB that consists of two compartments (). While the upper compartment holds the explants, the liquid culture medium is kept in the lower compartment. They are joined together and the medium is lifted into the upper chamber via the application of overpressure to the lower chamber. The liquid medium drops to the lower chamber when the overpressure falls. Details of the system for mass micropropagation have been reviewed elsewhere

[46][70][71]. Most reports claimed better multiplication rates in TIBs than on semi-solid media, although few observed no differences

[78][79][80]. In the lingonberry, Arigundam et al.

[75] reported the in vitro shoot proliferation of wild

V. vitis-idaea ssp.

minus clones in SB and TIB systems containing a liquid medium with 9.1 μM zeatin or 1.8 μM TDZ. The shoot proliferation was 2–3 times less on a semi-solid medium than in a liquid medium, although 10–25% of hyperhydric shoots were observed in bioreactors. However, the rooting of these shoots was not affected, as most of the bioreactor-cultured microshoots rooted in a peat—a perlite medium with 90–95% survivability under greenhouse conditions

[75]. This indicated that in lingonberry, the hyperhydricity was reversible, confirming the previous report with strawberry

[81].

Figure 2. In vitro culture of lingonberry in a recipient for automated temporary immersion (RITA) bioreactor.

3.1.2. Stationary Bioreactor (SB)

Stationary bioreactor is an effective system for the in vitro culture of lingonberries

[75]. The Growtek is a low-cost SB system that has been designed, patented and commercialized for in vitro propagation

[82]. The system is suitable for the increased proliferation rates of shoots. It saves time for incubation, minimizes contamination and helps in transferring plantlets, easily avoiding root injury. It has been applied for in vitro seed germination, molecular pharming, secondary metabolite production, culturing solid-state fungi and bioremediation. The SB contains a rotating and floating explant holder and a side tube that can be used for changing medium, feeding culture and monitoring contents (). Compared to agar-gelled and liquid media using other culture vessels, Dey

[82] reported that the Growtek SB bioreactor produced 1.2–23.3 times more shoots with reduced root injury (32–48%), contamination (12–18%) and incubation time (16–42%). Similar results were also reported in lingonberries by Arigundam et al.

[75], where shoot multiplication was much less on a semi-solid medium than in SB or TIB with a liquid medium. The healthier shoots can be obtained in a Growtek vessel due to the presence of a more appropriate vapor/gas phase inside the vessel. Growtek can be used both in static and agitated conditions and covers the qualities of both liquid and gelled media systems. The unique combination of these features can be effectively used for the biosynthesis of secondary metabolites in hairy roots and for in vitro propagation, including somatic embryogenesis

[82]. In the Growtek system, the higher thread rim depth helps improve the suitable gas exchange, thereby causing better shoot and root growth and vigor.

Figure 3. In vitro culture of lingonberry in a Growtek vessel.